Understanding Drywall Finish Levels: What You Need to Know

Finishing drywall is more complex than it may seem.

To achieve high-quality results, it’s important to understand not only the drywall finishing process (as outlined by the Gypsum Association (GA) and the Drywall Finishing Council (DWFC)), but also to use the right paint systems (Painting Contractors Association (PCA)) and products (Master Painters Institute (MPI)).

When these elements work together, the result is a finish that meets both performance and design expectations.

What Are Drywall Finish Levels?

Drywall Finish Levels are industry standards that define the steps required to finish a wall. They don’t guarantee what the final wall will look like, that outcome depends on factors like workmanship, site conditions, and paint systems.

That’s why mock-ups are strongly recommended at the start of a project. They help set a clear standard that design professionals, contractors, and building owners can all agree on before work progresses.

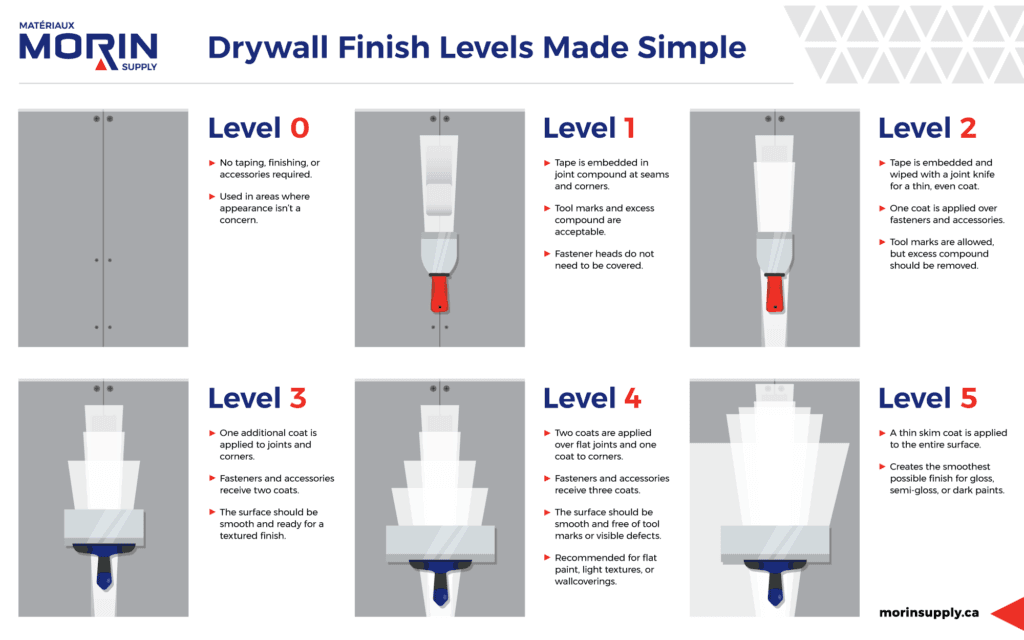

The 5 Levels of Drywall Finish

Levels 0 – 2: Performance-Focused

At these levels, visual appearance isn’t a priority. They are specified mainly for performance requirements.

- Level 0: Unfinished gypsum board.

- Level 1: Tape coat only.

- Level 2: Partially finished.

Levels 3 – 5: Appearance-Focused

These levels are specified when the aesthetic outcome matters. The design professional determines the appropriate finish level based on the project’s needs.

- Level 3: Finish suitable for medium to heavy textures.

- Level 4: Smooth finish for light or non-continuous, flat paint finishes and wall coverings.

- Level 5: Smooth finish designed for non-flat paints and glossy wallcoverings.

Each level has different tolerances, and mock-ups that include wall finishing are the best way to align expectations for the final look.

Does the Finish Level Guarantee the Final Look?

No. The finish level only specifies the steps required to reach that level, it doesn’t guarantee the visual result.

Several factors influence the final outcome:

Site Conditions

Site conditions play a significant role in both the quality of the finish and the time required to complete the work. Ready-mix compounds are water-based products that require optimal temperature and humidity levels to cure properly. Although the surface may feel dry, the curing process may not be complete. Applying paint or additional ready-mix over an uncured joint can reintroduce moisture, extending the curing time.

It is essential to maintain a controlled environment even after finishing levels are completed and cured. Similar to hardwood flooring, temperature and humidity must be kept stable post-installation to prevent issues.

Quality of Workmanship & Compliance

The quality of workmanship and adherence to association guidelines are the most critical factors in achieving the desired finish. Experienced interior systems contractors can provide references, mock-ups, and guidance to support a successful project. However, the responsibility for a finished wall extends to everyone on site. It is essential that all contractors make the necessary effort to ensure a high-quality final product.

Framing

Framing is the foundation of any successful drywall finish. While wood is an economical option, it comes with challenges compared to alternatives like steel studs. Understanding these challenges helps explain why drywall finishing on wood-framed walls requires careful attention.

Wood-Specific Challenges:

- Shrinkage, knots, and soft spots can lead to drywall cracks and screw pops.

- Warping can cause uneven or wavy walls & ceilings.

- Size variations make aligning drywall seams more difficult.

Structural Considerations (All Framing Types):

- Deflection and structural movement can create cracks and screw pops.

- Large surface areas and expansion may also contribute to cracks and screw pops.

By addressing both material-specific challenges and structural factors, contractors can achieve a smooth, durable, and high-quality wall finish.

Resources

For more detailed guidelines, visit:

- Gypsum Association (GA)

- Painting Contractors Association (PCA)

- Drywall Finishing Council DWFC

- Master Painters Institute (MPI)

Or contact Morin Supply – we’re here to provide expert guidance, materials, and support to ensure your next project is a success.